Agile Robots Unveils Agile ONE: Industrial Humanoid Built for European Manufacturing

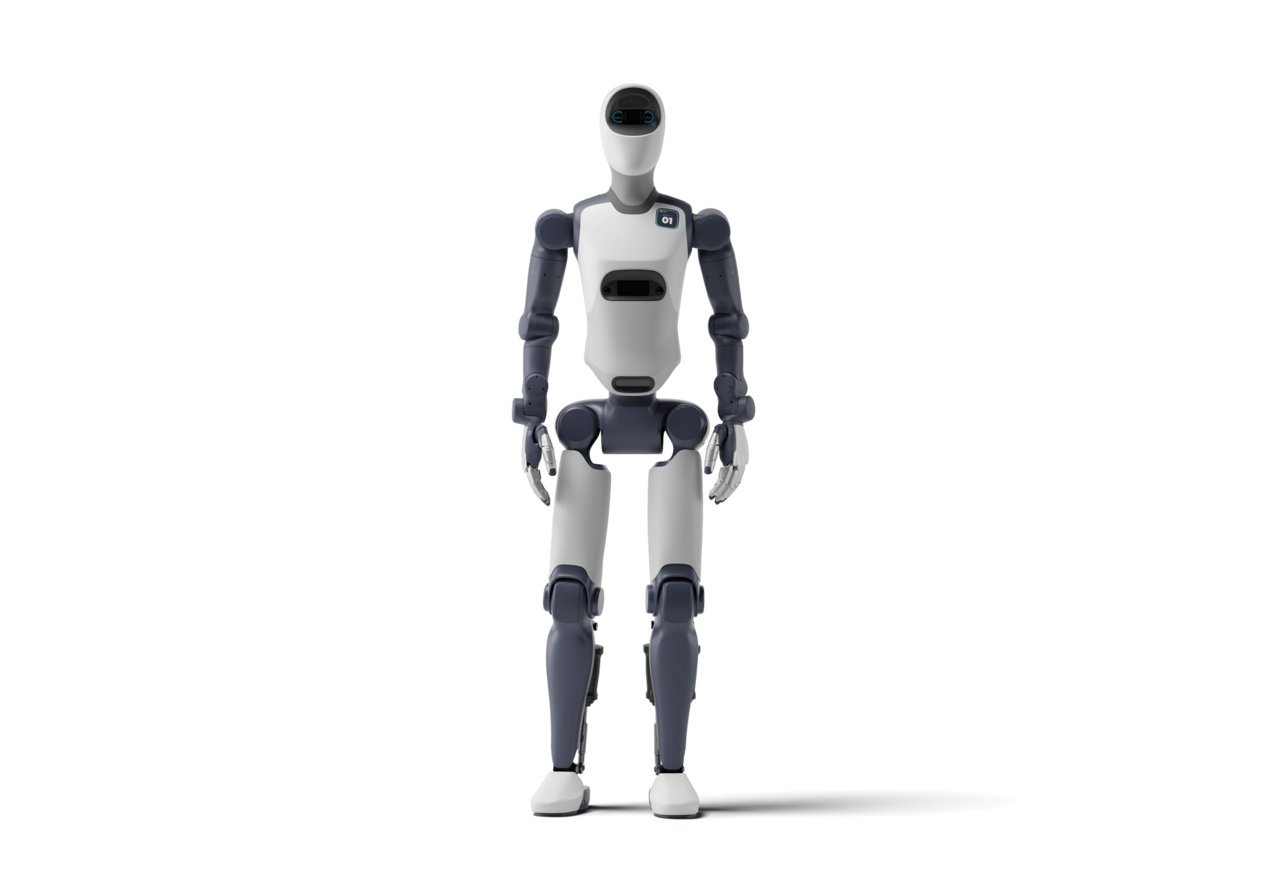

German robotics firm Agile Robots has introduced the Agile ONE, a humanoid robot engineered specifically for industrial applications in European manufacturing environments. The platform represents a significant advancement in physical AI for factory automation.

Agile Robots Launches Industrial Humanoid for European Manufacturing

German robotics company Agile Robots has unveiled the Agile ONE, a purpose-built humanoid robot designed to address labor challenges and operational demands in European manufacturing facilities. The platform marks a strategic entry into the industrial robotics market, targeting factories seeking flexible automation solutions that can adapt to complex, human-centric tasks.

Technical Architecture and Design

The Agile ONE represents a deliberate engineering approach to industrial humanoid robotics. Unlike general-purpose humanoid platforms, the system has been specifically optimized for manufacturing environments common across Europe, where production lines often require dexterous manipulation, dynamic task switching, and integration with existing factory infrastructure.

The robot's design emphasizes practical deployment considerations:

- Dexterity and precision for handling components and assembly tasks

- Physical robustness for continuous industrial operation

- Safety integration compliant with European manufacturing standards

- Scalable deployment across multiple production lines

Market Context and Strategic Positioning

The introduction of Agile ONE arrives amid growing demand for humanoid robots in manufacturing. European factories face persistent labor shortages and rising operational costs, creating compelling use cases for flexible automation platforms. Unlike traditional industrial robots confined to fixed workstations, humanoid systems can navigate dynamic factory environments and perform tasks requiring human-like adaptability.

Agile Robots positions the platform as part of the broader "physical AI" evolution—systems that combine advanced perception, decision-making, and motor control to execute complex real-world tasks autonomously or with minimal human intervention.

Manufacturing Applications

The Agile ONE targets several high-value manufacturing scenarios:

- Assembly operations requiring fine motor control and visual feedback

- Quality inspection and component handling

- Machine tending and material transfer between production stages

- Maintenance support in confined or hazardous spaces

These applications represent areas where traditional fixed-base industrial robots face limitations, yet human labor remains costly or difficult to source.

European Manufacturing Focus

The explicit focus on European factories reflects both regulatory and operational realities. European manufacturers operate under stringent safety and environmental standards, necessitating robots with sophisticated safety systems and compliance certifications. Additionally, European labor markets and wage structures create stronger economic incentives for automation investment compared to regions with lower labor costs.

Integration and Deployment Considerations

Successful deployment of humanoid robots in existing manufacturing environments requires careful integration planning. Factories must address:

- Workflow adaptation to accommodate robot capabilities and limitations

- Safety protocols ensuring human-robot collaboration where applicable

- Maintenance and support infrastructure

- Training for operators and technical staff

Looking Forward

The launch of Agile ONE signals intensifying competition in the industrial humanoid robotics space. As multiple companies develop manufacturing-focused humanoid platforms, differentiation will increasingly depend on real-world performance metrics, reliability in production environments, and total cost of ownership over extended deployment periods.

For European manufacturers evaluating automation investments, the availability of purpose-built humanoid systems expands the toolkit beyond traditional industrial robots, offering potential solutions to labor constraints and operational flexibility challenges.

Key Sources

- Agile Robots SE official product documentation and announcements

- The Robot Report coverage of Agile Robots industrial robotics developments

- Interesting Engineering analysis of German industrial robotics innovations