From Lab to Factory Floor: Humanoid Robots Enter Manufacturing

Humanoid robots are transitioning from trade show demonstrations to real-world factory deployment, with major manufacturers like Hyundai leading the charge. What does this mean for industrial labor?

The Manufacturing Inflection Point

The humanoid robot industry has reached a critical threshold. After years of polished demonstrations at tech conferences, these machines are now moving into actual production facilities—and the implications are reshaping how companies think about factory automation. According to the International Federation of Robotics, humanoid robots represent one of the top five global robotics trends for 2026, signaling that the transition from prototype to production is no longer theoretical.

Hyundai's recent partnership with Boston Dynamics exemplifies this shift. The South Korean automotive giant is deploying humanoid robots in manufacturing environments, moving beyond the controlled environment of research labs and into the messy reality of factory floors. This isn't about replacing workers wholesale—it's about tackling the specific bottlenecks that have plagued manufacturers for decades.

Why Humanoids Matter in Manufacturing

Unlike traditional industrial robots, humanoid robots offer a critical advantage: they're designed to work in spaces built for humans. Factories don't need to be retrofitted with specialized cages or conveyor systems. A humanoid can pick up a tool, navigate stairs, and adapt to variations in task execution—capabilities that rigid, single-purpose robots simply cannot match.

The practical applications emerging in 2026 include:

- Assembly line tasks requiring dexterity and spatial reasoning

- Quality inspection in confined or hazardous areas

- Material handling in non-standardized environments

- Maintenance operations that demand problem-solving on the fly

Trade shows in 2026 have showcased nine distinct humanoid robot models competing for industrial contracts, indicating genuine market momentum rather than speculative hype.

The Labor Question

The deployment of humanoid robots in manufacturing raises an unavoidable tension. Hyundai's move comes amid political pressure to expand domestic manufacturing jobs, yet the company is introducing automation that could reduce headcount. This paradox reflects the reality of modern manufacturing: productivity gains and employment growth are increasingly difficult to achieve simultaneously.

However, industry observers note that humanoid robots are filling genuine labor gaps. Repetitive, dangerous, or physically demanding tasks that workers actively avoid are prime candidates for automation. The question isn't whether robots will enter factories—it's whether they'll displace workers or augment existing teams.

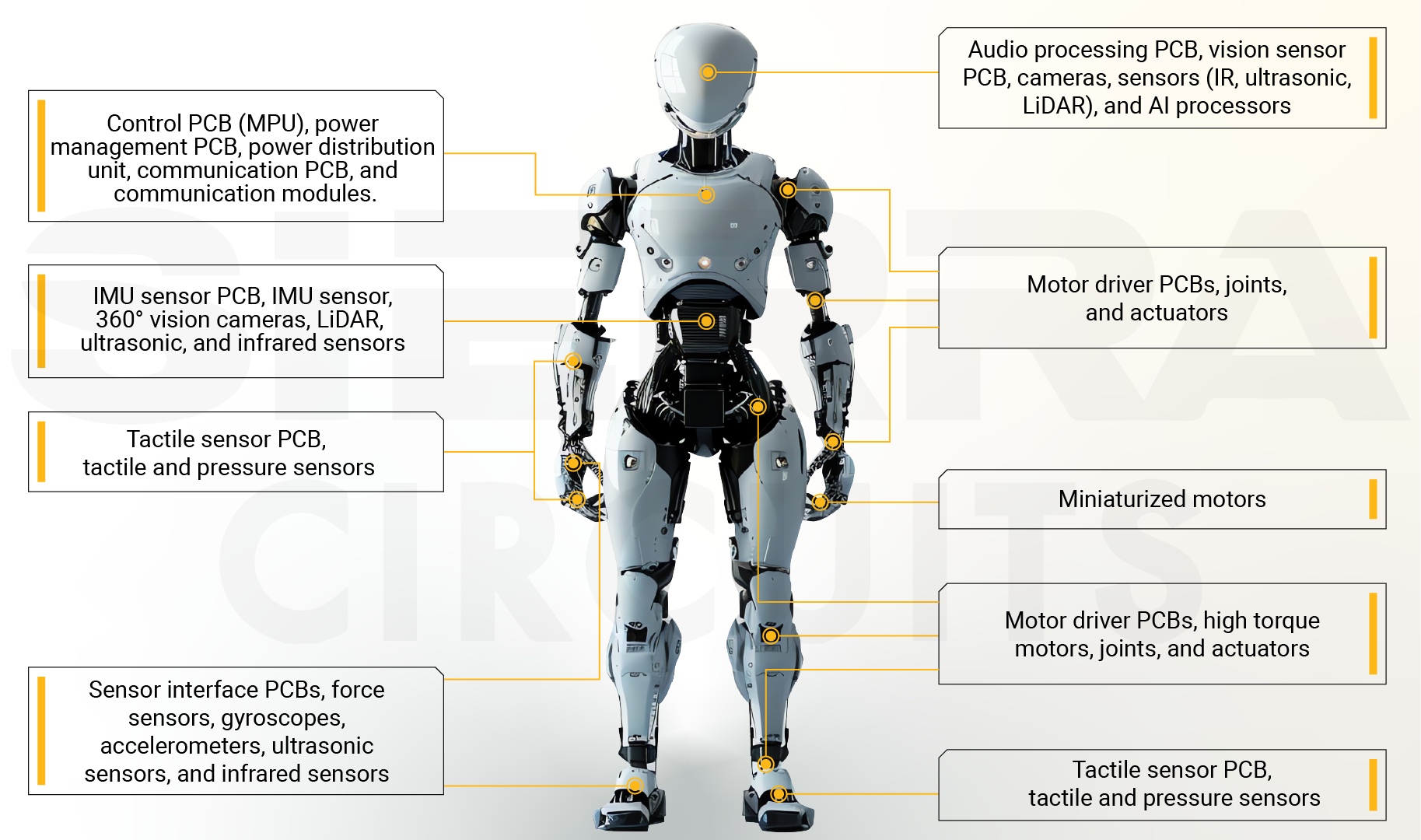

Technical Challenges Remain

Despite the momentum, significant hurdles persist. Control systems for humanoid robots in industrial settings are still evolving, and reliability in unstructured environments remains a work in progress. Battery life, cost per unit, and the need for human oversight in complex scenarios all constrain near-term deployment.

What's Next

The transition from demonstration to deployment is underway, but it's not a straight line. Manufacturers are cautiously integrating humanoid robots into specific roles, measuring performance, and adjusting expectations. Success will depend on whether these machines can deliver consistent productivity gains while remaining cost-effective relative to human labor.

The humanoid robot era in manufacturing isn't coming—it's already here. What happens next depends on how quickly the technology matures and how society chooses to manage the transition.